Advice on buying reversing cameras

Most people buying a reversing camera will have very little knowledge about them. We hope that within our web site we give enough information to help in your choice of reversing camera.

The reversing camera sensor

This is the most important part of the reversing camera as it controls the quality of the image the camera can produce.

The sensor is the part that captures the image. They can be CCD or CMOS technology. The CCD is considered the best for reversing cameras as they give the best resolution, daytime colour and good night vision. CMOS generally give a weaker picture especially at night, but more modern versions have closed the gap with CCD. CCD are more expensive and take more support electronics so are found in larger cameras. The sensor itself come in a variety of grades depending on their production. Some will be sold off cheaply to be used in systems that do not require a perfect picture such as lane departure warning systems. A good quality camera sensor, support board and lens will cost more than a complete camera on ebay or Amazon.

The 2 big manufacturers of CCD sensors are Sony and Sharp. The support boards are generally produced in Taiwan or South Korea. Another area where there can be a big difference in quality is the lens. Higher resolution CCD chips require a lens capable of matching the resolution which adds to their cost. Cheap cameras often used pressed plastic lenses.

With CMOS Micron and OV are two of the big producers. They have improved considerably over the recent years to the point that some cameras advertised as CCD actually have the cheaper CMOS sensors inside. More recently Sony have introduced a range of CMOS sensors. These show a lot of promise and will out perform the CCD sensor. Sony eventually will stop production of their CCD range. Many of our AHD cameras use the Sony CMOS sensor.

We use a large version of this chart to double check reversing cameras we receive. Using it you can see if the sensor performance is the same as you would expect. In particular you can identify the number of TVL the camera is capable of.

A more recent development is the use of high resolution CMOS sensors in AHD cameras. These give the best performance of all the cameras currently on the market. In the coming months there will be a range of these available on our web site. AHD format cameras will only work with the more modern AHD monitors. There are currently a lot of AHD equipment for sale cheaply as the development of the technology has resulted in a lot of rejects. AHD can usually be recognised as they will talk about it being 720P, 840P or 1080P in its specifications.

Camera angle

The specifications for cameras will include a range of data most of which you can ignore. The one that is important is camera angle. It is also the one that is the most likely to be wrong!! On most of our cameras we will have added or are about to add our measured camera angle. It is the most reliable way of getting a correct number. Camera angles are usually measured diagonally. The most common angle is 120 degrees which offers a wide field of view without suffering from the "fish eye" effect which can cause quite bad distortion in wider angled cameras. Other camera angles include 60 and 150 degrees. Some cameras either use an aspheric lens or software processing to reduce the distortion.

Most people want a wide angled camera so the can get the field of view to spot obstacles close to the bumper. Wide angled cameras do distort distances making something close in look a long way back. This is why people who want to use a camera continuously as a rear view camera often prefer a 60 degree lens. The following photograph compares them.

Waterproof rating

Reversing cameras will have a waterproof rating (or IP rating) of either IP67 or IP68. The 6 tells you it is totally protected against dust. The 7 says it is protected against immersion in water between 15cm and 1m for a duration of at least 30 min. The 8 says it is protected against long periods of immersion to a depth of 3m (under pressure). The great problem with the IP test is it does not reproduce real life conditions. On the IP67 test the pressure inside the camera will prevent the water getting in even if there is a potential place for a leak to occur. Our main camera supplier now uses a test where they alternate the cameras between hot and cold water tanks. This reproduces a typical scenario where a camera is hot because of the sun the cools suddenly in a rain shower. Fortunately we find water ingress is not a major issue on ouir cameras. The design is such that they have rubber seals on the glass and between the housings. We have seen cheaper cameras where they simply use glue as a seal. This breaks fairly quickly as the camera expands and contracts with change in temperature. It is cheaper for the manufacturer to make cameras that way.

Types of connection

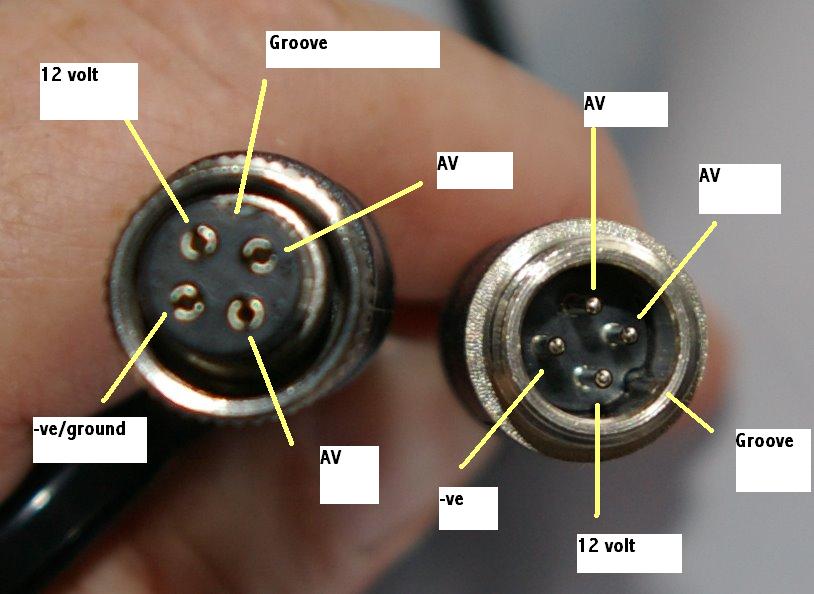

There has never been a standard connector produced for a reversing camera. We have met so many variations that we have produced a separate information section to help people deal with them. Our cameras either use standard RCA (phono) plugs and sockets or the 4 pin aviation style. The great advantage of the 4 pin aviation style is they are slowly becoming the normal connection. Details are shown in the photograph below.

Wiring arrangements

The reversing camera systems based on the 4 pin aviation connector are the easiest to wire is as they are powered directly from the monitor. This means they can be turned on and off as required and benefit from the protection built into the monitors power supply. The cameras based on RCA connectors are usually wired in to take power off the reversing light. With modern cars this can be an issue as CANBUS systems may detect the extra current drain as show a bulb failure warning light. You can usually get around this by either taking power off the ignition at the front for all the time the ignition is on or using a relay to switch it on and off. With some cars modern LED lights and multiplex lighting make finding a power supply at the back a job for the professional.

Where to place a camera

The ideal place for a reversing camera is up high angle angled down. This gives a birds eye view and takes any guesswork out of reversing. As you come down towards the number plate you lose sight of the corners of the vehicle, but gain more view back down the road. You also increase the risk of getting glare from the sun and more road dirt on the lens/glass front of the camera. Some camera can be really small and are very discrete and some are large and very obvious. The decision on where to locate the camera will very much depend on the vehicle you are fitting it to.

Camera problems

The main thing that can go wrong with a camera is when fitting you get the +ve and -ve leads mixed up. Reversed polarity = smoke and a dead camera. After that the biggest enemy is water. Although the cameras are fully waterproof we advise they are not pressure washed. If you think the camera is in an area where high pressure jets may hit it then try to protect it in some way. Cameras are subject to vibration and rapid temperature changes and are in quite a hostile environment. They can fail for this reason over time. With our cameras the 12 month guarantee means we replace any camera that fails (except the ones you melt fitting!) with a new one. Fortunately we do not have to do this very often.

To look after your camera we recommend you avoid pressure washing them. It helps the night image if you avoid getting wax on the front glass of cameras fitted with IR LEDs. Corrosion can be a problem on some cameras. The bullet style cameras tend to be extruded aluminium which in our experience cope very well with the winter salt. . On our bracket style cameras we use a shell with a high aluminium content. They cost a little more, but it does help limit corrosion. We also use stainless steel to make the brackets where possible. It helps to wipe them clean and wax the outer body on a regular basis. If the paint does get damaged, then in winter when there is salt on the road they will corrode. Repairing the damage quickly will greatly extend the life of the camera. The cheap heavy cameras with a high zinc content will begin to corrode the first time it rains. If you wish to confirm this there are plenty of Chinese sellers who have them on ebay!

Corrosion is a issue that affects all reversing cameras as the photograph above demonstrates. You can pay for expensive cameras from a well known brand and they can still corrode if not looked after. The camera had been fitted 18 months. We are working to solve the issue but plastic cameras leak, anti-corrosion coatings do not work and fibreglass housings tend to accelerate the corrosion as it traps in moisture.

Vibration testing

We often get asked how well our cameras stand up to vibration. Below is our test vehicle!

Neil has a MON705 and 2 CAM022s fitted to his Monster Truck to help ensure everyone's safety. They spend the day getting bounced around along with members of the public. You can get to ride on the Monster Truck at many of the motor racing events around the country.